-

Stainless Steel Raw Materials

0.01—5.0

Send Email Details

Customized according to drawings

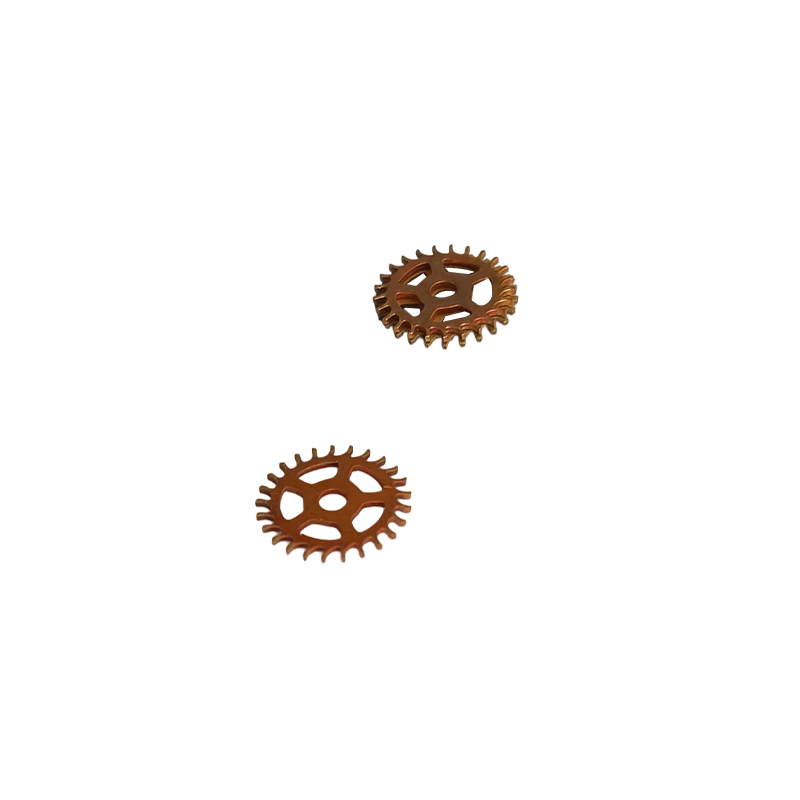

Brass: copper-zinc alloy, golden in color, high in hardness and wear-resistant, commonly used in valves, pipe fittings, etc.

Red copper: pure copper (copper content more than 99%), purple-red in color, excellent in electrical and thermal conductivity, mostly used in wires and cables.

Phosphorus copper: copper-tin-phosphorus alloy, good in elasticity and fatigue resistance, mainly used in springs and electrical connectors. -

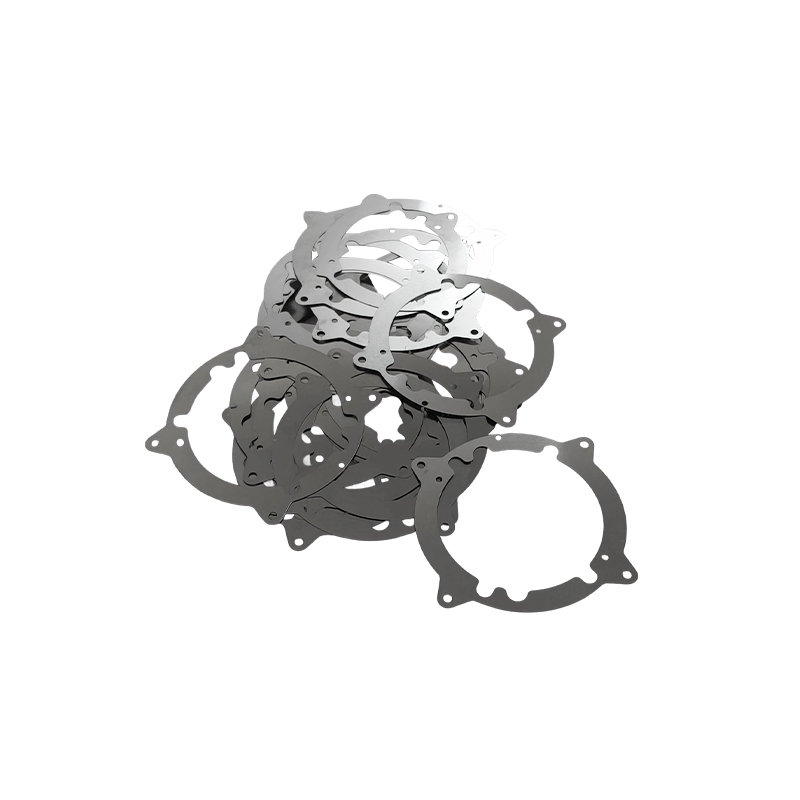

Stainless Steel 301/304/316/420/430/630 Etc.

0.01—5.0

Send Email Details

Customized according to drawings

301: Low nickel content, high cold working strength, used for springs and knives.

304: General model, good corrosion resistance, commonly used in tableware and kitchenware.

316: Added molybdenum, acid and alkali resistant, seawater resistant, commonly used in medical and chemical equipment.

420: Martensitic steel, hardened after quenching, used as knives and surgical instruments.

430: Ferritic steel, oxidation resistant, used for home appliance panels.

630: Precipitation hardening steel, high strength, used in aviation and nuclear industries. -

65Mn Manganese Steel Laser Cutting

0.01—5.0

Send Email Details

Customized according to drawings

65Mn manganese steel is a medium-carbon high-manganese steel with good toughness and wear resistance. Its laser cutting process uses a high-energy laser beam to melt or vaporize the material, and the cutting trajectory is accurately controlled by the CNC system. During processing, attention should be paid to the hardness change caused by the heat-affected zone. It is often used for precision cutting and forming of parts such as springs and tools. -

1060/5052/6061/6063/Etc. Laser Processing

0.01—5.0

Send Email Details

Customized according to drawings

1060: Pure aluminum, easy to melt during laser processing, suitable for thin plate cutting, used for aluminum foil and signs.

5052: Aluminum-magnesium alloy, corrosion-resistant, laser processing requires controlled thermal deformation, used for ships and pressure vessels.

6061/6063: Aluminum-magnesium-silicon alloy, 6061 has high strength, 6063 has good precision, laser processing is often used for aviation parts and profile cutting, and attention should be paid to heat dissipation and crack prevention. -

4j29/C276/2080/1j85/N6 And Other Laser Processing

0.01—5.0

Send Email Details

Customized according to drawings

4J29: Iron-nickel-cobalt alloy (Kovar alloy), laser processing requires controlled thermal expansion, used for electronic packaging.

C276: Hastelloy, nickel-molybdenum-chromium alloy, strong corrosion resistance, laser cutting requires high power to prevent heat-affected zone corrosion.

2080: Nickel-based high-temperature alloy, laser processing requires temperature control to prevent coarse grains, used for aviation parts.

1J85: Iron-nickel soft magnetic alloy, laser processing avoids annealing to affect magnetic properties, used for magnetic cores.

N6: Pure nickel, good thermal conductivity, laser processing requires concentrated energy, used for batteries and electric vacuum devices.