How does 65mn manganese steel laser cutting easily reveal complex shapes with stunning results?

Release Time : 2026-01-09

65Mn manganese steel, a high-carbon, high-manganese alloy spring steel, is widely used in the manufacture of springs, cutting tools, fixtures, agricultural machinery parts, automotive components, and various precision mechanical structural parts due to its excellent elasticity, wear resistance, fatigue resistance, and high strength. However, its high hardness and toughness also pose challenges to traditional machining methods—low efficiency, numerous burrs, and large heat-affected zones make it difficult to meet the demands of modern industry for complex geometries and high-precision contours. 65mn manganese steel laser cutting has achieved a revolutionary breakthrough: complex shapes can be easily revealed, with smooth edges, precise dimensions, and doubled efficiency, resulting in stunning application effects.

1. How does laser cutting overcome the machining challenges of 65Mn manganese steel?

65Mn steel contains approximately 0.62%–0.70% carbon, and its hardness can reach over HRC45 after heat treatment. Traditional machining methods easily lead to rapid tool wear and even chipping. Laser cutting utilizes a non-contact, high-energy laser beam to melt or vaporize materials, completely avoiding mechanical stress and tool wear. By optimizing laser power, cutting speed, auxiliary gas pressure, and focal point position, efficient cutting of 1–10mm thick 65Mn steel plates can be achieved. Especially when using nitrogen as the auxiliary gas, the cut surface exhibits minimal oxidation and a silvery-white metallic luster, requiring almost no subsequent polishing and directly meeting high-end assembly requirements.

2. Precise "Replication" Capability of Complex Geometric Shapes

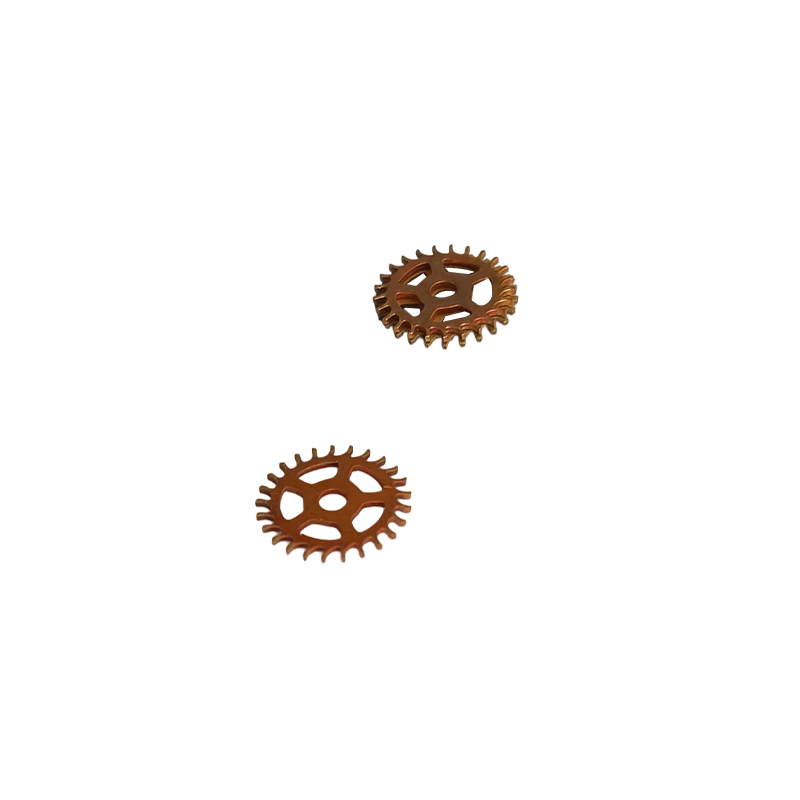

Thanks to the high responsiveness of the CNC system and the micron-level focusing capability of the laser beam, 65Mn manganese steel laser cutting can produce extremely fine internal angles, dense arrays of holes, irregular curved surfaces, and even intricate artistic patterns. For example, wavy edges and porous weight-reducing structures commonly found in agricultural machinery springs or automotive clutch plates, which traditional processes require multiple steps to complete, can be achieved with laser cutting in a single operation, achieving a positioning accuracy within ±0.1mm. Even more commendable is the ability to achieve sharp corners with a radius of less than 0.5mm, even on 8mm thick 65Mn plates, fully unleashing the designer's imagination for structural function and aesthetic form.

3. Heat-Affected Zone Control and Material Property Preservation

Although laser cutting is a thermal process, modern pulse modulation and high-speed cutting technologies have significantly reduced the heat-affected zone. Through precise control of cutting parameters, the HAZ of 65Mn steel can be controlled within 0.1–0.3mm, effectively avoiding hardness reduction or residual stress concentration caused by localized annealing. For spring-like parts that require subsequent quenching and tempering, this low-heat-input cutting method provides a more uniform initial microstructure for heat treatment, helping to improve the fatigue life and elastic stability of the final product.

4. Significant Efficiency Improvement and Flexible Manufacturing Advantages

Compared to the processing speed of only a few centimeters per hour for wire cutting, 65mn manganese steel laser cutting can increase efficiency by more than 10 times. A single 2m x 1m sheet can be used to cut hundreds of complex parts within 30 minutes, supporting automated loading and unloading and intelligent layout software to optimize material utilization, reducing scrap rate by 15%–20%. Furthermore, no mold development is required, making it particularly suitable for small-batch, multi-variety customized production—whether it's prototyping new products or urgently needed replacement parts, it allows for rapid response, greatly enhancing a company's flexible manufacturing capabilities.

65Mn manganese steel laser cutting technology not only solves the efficiency and precision bottlenecks of traditional processing but also opens up new possibilities for complex structural designs. From industrial springs to precision cutting tools, from core components of agricultural machinery to high-end decorative components, laser cutting is giving this classic alloy material unprecedented expressiveness and competitiveness. When "complexity" no longer means "expensive" and "inefficient," the application boundaries of 65Mn manganese steel are being redefined.

1. How does laser cutting overcome the machining challenges of 65Mn manganese steel?

65Mn steel contains approximately 0.62%–0.70% carbon, and its hardness can reach over HRC45 after heat treatment. Traditional machining methods easily lead to rapid tool wear and even chipping. Laser cutting utilizes a non-contact, high-energy laser beam to melt or vaporize materials, completely avoiding mechanical stress and tool wear. By optimizing laser power, cutting speed, auxiliary gas pressure, and focal point position, efficient cutting of 1–10mm thick 65Mn steel plates can be achieved. Especially when using nitrogen as the auxiliary gas, the cut surface exhibits minimal oxidation and a silvery-white metallic luster, requiring almost no subsequent polishing and directly meeting high-end assembly requirements.

2. Precise "Replication" Capability of Complex Geometric Shapes

Thanks to the high responsiveness of the CNC system and the micron-level focusing capability of the laser beam, 65Mn manganese steel laser cutting can produce extremely fine internal angles, dense arrays of holes, irregular curved surfaces, and even intricate artistic patterns. For example, wavy edges and porous weight-reducing structures commonly found in agricultural machinery springs or automotive clutch plates, which traditional processes require multiple steps to complete, can be achieved with laser cutting in a single operation, achieving a positioning accuracy within ±0.1mm. Even more commendable is the ability to achieve sharp corners with a radius of less than 0.5mm, even on 8mm thick 65Mn plates, fully unleashing the designer's imagination for structural function and aesthetic form.

3. Heat-Affected Zone Control and Material Property Preservation

Although laser cutting is a thermal process, modern pulse modulation and high-speed cutting technologies have significantly reduced the heat-affected zone. Through precise control of cutting parameters, the HAZ of 65Mn steel can be controlled within 0.1–0.3mm, effectively avoiding hardness reduction or residual stress concentration caused by localized annealing. For spring-like parts that require subsequent quenching and tempering, this low-heat-input cutting method provides a more uniform initial microstructure for heat treatment, helping to improve the fatigue life and elastic stability of the final product.

4. Significant Efficiency Improvement and Flexible Manufacturing Advantages

Compared to the processing speed of only a few centimeters per hour for wire cutting, 65mn manganese steel laser cutting can increase efficiency by more than 10 times. A single 2m x 1m sheet can be used to cut hundreds of complex parts within 30 minutes, supporting automated loading and unloading and intelligent layout software to optimize material utilization, reducing scrap rate by 15%–20%. Furthermore, no mold development is required, making it particularly suitable for small-batch, multi-variety customized production—whether it's prototyping new products or urgently needed replacement parts, it allows for rapid response, greatly enhancing a company's flexible manufacturing capabilities.

65Mn manganese steel laser cutting technology not only solves the efficiency and precision bottlenecks of traditional processing but also opens up new possibilities for complex structural designs. From industrial springs to precision cutting tools, from core components of agricultural machinery to high-end decorative components, laser cutting is giving this classic alloy material unprecedented expressiveness and competitiveness. When "complexity" no longer means "expensive" and "inefficient," the application boundaries of 65Mn manganese steel are being redefined.